It allows to keep PV going, with more focus towards AI, but keeping be one of the few truly independent places.

-

Worldwide sales of semiconductor manufacturing equipment surged 19% from US$59.8 billion in 2019 to a new all-time high of US$71.2 billion in 2020, according to SEMI.

China claimed the largest market for new semiconductor equipment with sales growth of 39% to US$18.72 billion.

Sales in Taiwan, the second-largest equipment market, remained flat in 2020 with sales of US$17.15 billion after showing strong growth in 2019, SEMI said. Korea registered 61% growth to US$16.08 billion to sit in third.

Annual spending also increased 21% in Japan and 16% in Europe as both regions are recovering from the contraction in 2019, SEMI continued. Receipts in North America decreased 20% in 2020 following three years of consecutive growth.

Bad things coming, as up to 60% of money spent came for free from governments.

-

Industry sources of shortages

Industry source told that semiconductor shortages have nothing to do with market conditions but is mainly disinformation made to hide big inflation in the sector. Talking about shortages allow to shift the blame.

-

In its first budget proposal to Congress on Friday, the White House called for new funding to fight the ongoing semiconductor shortage.

Among other measures, the White House’s budget request includes $150 million to fund two new manufacturing programs, including one targeting domestic semiconductor manufacturing

The “American Jobs Plan,” the sweeping $2 trillion infrastructure package unveiled in March, also included new funding to build domestic chip manufacturing capacity, allocating over $50 billion for investment in the sector

They need money and lot of them, for free.

-

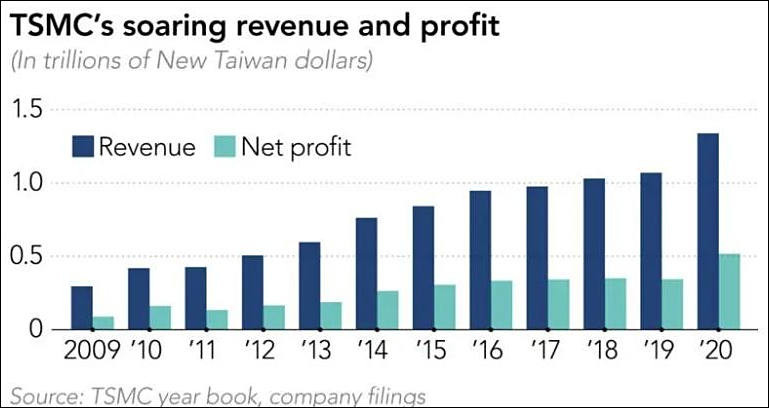

TSMC's consolidated revenue for March and first-quarter 2021 both set record highs.

TSMC reported revenue for March 2021 climbed 21.2% sequentially and 13.7% on year to NT$129.13 billion (US$4.54 billion).

TSMC's revenue for March 2021 outpaced the previous record high set in September 2020.

Criminals.

-

Chip shortages may start easing as early as the first half of 2022, according to CK Tseng, president for Arm Taiwan.

Tight capacity at foundries has led to shortages of many chips, which is unlikely to be relieved until at least the first half of next year, said Tseng at a press conference in Taipei on March 31.

Every capitalist want to gain something even during war. Same here. Industry pulled all stops, started making fake shortages, promote them to media, causing real new orders rush and covering first lies with them.

-

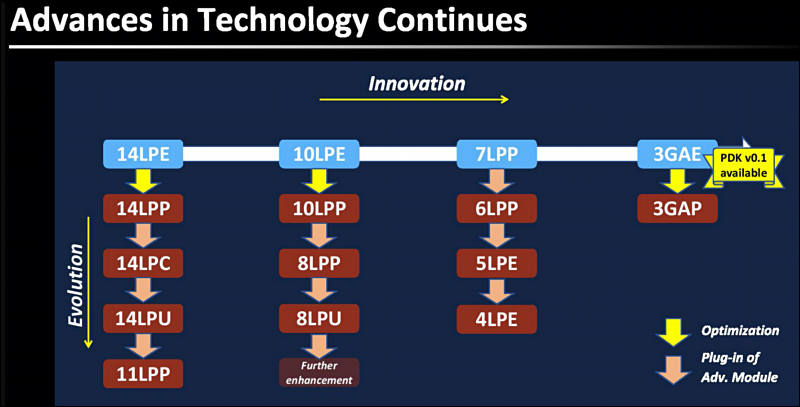

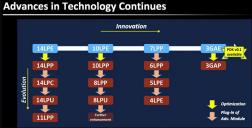

According to employees at Intel's Hillsborough, Oregon plant, the company intends to rename (to make them look better!) its manufacturing processes. Announcement of this came from Ann Kelleher, head of Intel's technology development department. In the opinion of the company's management, the current numbering does not reflect the leading technological position of Intel in the production of chips, and this point needs to be clarified.

Historically, at the stage of transition from 90- to 32-nm technological processes, the definition of technological standards of production for each company has become special. There is a universal metric that could reveal the details of the technical process - this is the minimum step of the line projected onto the crystal. However, this approach cannot effectively advertise products. Therefore, the geometry of the transistors, the step of their arrangement on the crystal, the number of transistors in the cache memory cell, and much more were used.

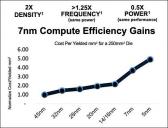

To date, the marketing of Samsung and TSMC has clearly suppressed Intel's marketing. The first and the second are already getting ready to release "3nm chips" next year, and Intel will start producing "7nm processors" only a year or two after that.

The battle of marketers while the real progress sucks.

-

The current short supply of semiconductor fab capacity is not normal, as the overall capacity should be more than enough to satisfy all demand in normal times, according TSMC chairman Mark Liu, who describes as "economically unrealistic" attempts by the US and Europe to expand their own fab capacity to satisfy all of their needs.

Interesting, as this guy practically eats billions of US and EU money each month.

-

TSMC will move N4 (namely 4nm process) to volume production in the fourth quarter of 2021, ahead of the 2022 timeframe set previously, according to sources at fab toolmakers.

It is very good for TSMC marketing team as rebranding 5nm into 4nm (by adding small improvements) will pour billions into PR and advertising machines.

-

$20 billions from new US stimulus will be given to Intel to make factories

Intel has announced plans to invest about US$20 billion to build two new fabs in Arizona in line with what it calls its IDM 2.0 strategy, seeking to become a major provider of foundry capacity in the US and Europe to serve worldwide customers.

"We are setting a course for a new era of innovation and product leadership at Intel," said Intel CEO Pat Gelsinger in a webcast where he announced the company's IDM 2.0 manufacturing expansion plans.

"Intel is the only company with the depth and breadth of software, silicon and platforms, packaging, and process with at-scale manufacturing customers can depend on for their next-generation innovations. IDM 2.0 is an elegant strategy that only Intel can deliver - and it's a winning formula. We will use it to design the best products and manufacture them in the best way possible for every category we compete in."

To accelerate the IDM 2.0 strategy, Gelsinger said two new fabs will be built in Arizona at at the company's Ocotillo campus. These fabs will support the increasing requirements of Intel's current products and customers, as well as provide committed capacity for foundry customers, he said.

This build-out represents an estimated investment of about US$20 billion, which is expected to create over 3,000 permanent high-tech, high-wage jobs, over 3,000 construction jobs, and approximately 15,000 local long-term jobs, said Gelsinger.

"We are excited to be partnering with the state of Arizona and the Biden administration on incentives that spur this type of domestic investment," he added.

Intel expects to accelerate capital investments beyond Arizona, and Gelsinger said he plans to announce the next phase of capacity expansions in the US, Europe and other global locations within the year.

Gelsinger reaffirmed the company's expectation to continue manufacturing the majority of its products internally. The company's 7nm development is progressing well, driven by increased use of extreme ultraviolet lithography (EUV) in a rearchitected, simplified process flow. Intel expects to tape in the compute tile for its first 7nm client CPU (code-named Meteor Lake) in the second quarter of this year.

-

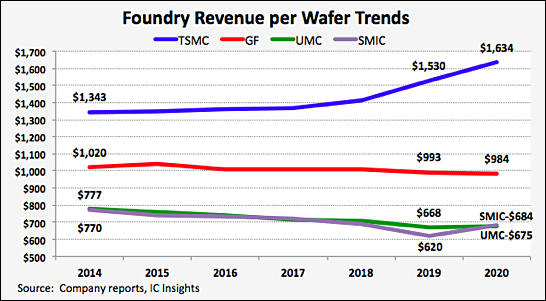

Supply in the semiconductor market has been so tight that prices in many segments, including foundry services, have been rising. Taiwan's pure-play foundry houses are now in contract talks with clients for 2022, and they are looking to introduce floating price schemes to make sure their pricing will reflect the volatility in costs, supply and demand.

More inflation and fuzzy future.

-

Renesas Electronics Corp., one of the biggest makers of automotive chips, said a fire halted production at one of its Japanese plants. The incident may exacerbate a shortage of semiconductors that has already curbed vehicle output across the industry.

The company said it’s still trying to ascertain the amount of damage in the clean room of its N3 building in Hitachinaka, Ibaraki Prefecture. There were no casualties. Clean rooms are designed to keep impurities from contaminating semiconductors, so fire damage has the potential to severely disable production.

“While there was no damage to the building, we confirmed damages to some of the utility equipment,” the company said in a statement. “We have been unable to confirm the safety of the clean room, which is the site of the fire, we have been unable to enter the clean room and determine the cause of the fire.”

One thing after another.

-

TSMC, United Microelectronics (UMC), Vanguard International Semiconductor (VIS) and Powerchip Semiconductor Manufacturing (PSMC) continue to run at full capacity for their 28nm and above process technologies.

Most factories are able to drop 28nm and above prices by 2-3 times if they will add new production lines, but they are not doing it for years (say thanks to cartel agreements). Because they want simple way to get big money.

-

Samsung 3nm update

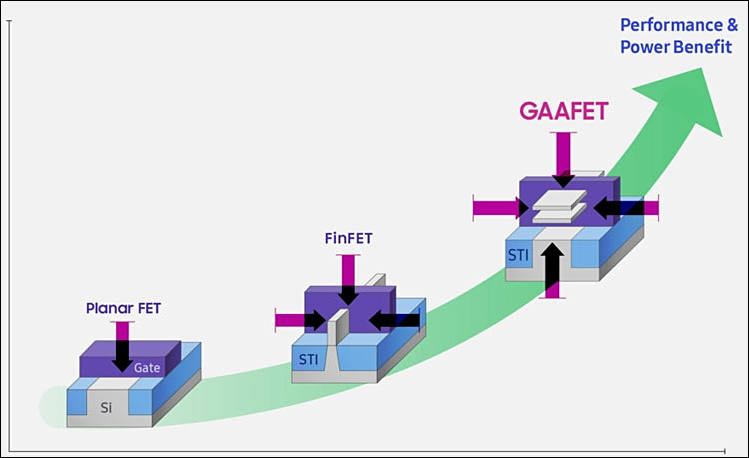

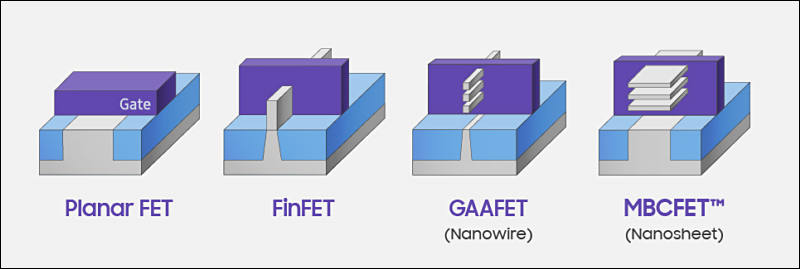

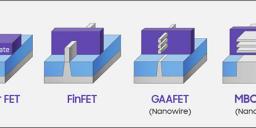

Samsung Foundry will be the first maker of semiconductors to start using gate-all-around field-effect transistor (GAAFET)-like structures with its upcoming 3 nm fabrication process. The node is not quite ready for primetime yet, but at the IEEE International Solid-State Circuits Conference (ISSCC) engineers from Samsung Foundry shared some of the details about the upcoming 3 nm GAE MBCFET (multi-bridge channel FET) manufacturing technology.

Formally, there are two types of GAAFETs: typical GAAFETs called nanowires that feature 'thin' fins as well as MBCFETs called nanosheets that use 'thicker' fins. In both cases, the gate material surrounds the channel region on all sides. Actual implementations of both nanowires and nanosheets heavily depend on design, so in general many industry observers describe both with one term, GAAFETs. But previously they were known as surrounding-gate transistors (SGTs). Meanwhile, MBCFET is a trademark of Samsung.

The first GAAFETs were demonstrated in 1988, so the key advantages of the technology are pretty well known. The very structure of this type of transistor allows designers to precisely tune them for high performance or low power by adjusting width of the transistor channel (also known as effective width, or Weff); wider sheets enable higher performance at higher power while thinner/narrower sheets reduce power consumption and performance. To do something similar with FinFETs, engineers have to use additional fins in a bid to improve performance. But in this case the 'width' of the transistor channel can only be doubled or tripled, which is not really precise and sometimes inefficient. In addition, adjustments of GAAFETs allow for increased transistor density, as different transistors can be used for different purposes.

sa16702.jpg749 x 458 - 34K

sa16702.jpg749 x 458 - 34K

sa16703.jpg800 x 269 - 28K

sa16703.jpg800 x 269 - 28K

sa16704.jpg800 x 407 - 50K

sa16704.jpg800 x 407 - 50K -

On March 4, 2021, as part of its ongoing efforts to realign its investments to focus on growth drivers and key markets and streamline its operations, ON Semiconductor Corporation (the “Company”) plans to implement certain employee terminations during the first half of 2021 (the “Employment Separations”). The Employment Separations will impact approximately 740 of the Company’s and its subsidiaries’ employees globally. The Company estimates that it will incur between $58 million and $62 million in aggregate costs during the first half of 2021.

The Company plans to reinvest a substantial portion of the savings generated from the Employment Separations into its continuing workforce and certain business initiatives and opportunities. Consequently, the restructuring may not result in a material reduction in the Company’s future operating expenses. The Company intends to continue to evaluate measures to realign its investments to achieve the Company’s strategic and transformational goals.

https://www.sec.gov/ix?doc=/Archives/edgar/data/1097864/000119312521069468/d131412d8k.htm

-

At present, according to analysts at Dalton Investments, three quarters of the world's production of complex semiconductor components is concentrated at TSMC and Samsung Electronics.

Moreover, if we consider 7nm and finer technical processes, then these companies control the entire volume of production. Intel's attempts to master 7nm technology have not yet materialized in the production of serial products

New duopoly is forming.

-

More issues

The shortage of semiconductor chips is gradually increasing in the world. Experts estimate the volume of the deficit at 10-30%. Any additional negative factor can increase the shortage of components, which, of course, affects all other industries - the production of laptops, desktops, servers, even cars. And such factor exists now -Samsung Corporation has not yet resumed semiconductor production at its US factory in Texas.

The problem started in mid-February - then in Texas there was an unprecedented cold, which required increased energy consumption. The South Korean company was forced to stop the work of two factories in Austin at once. The decision was unprecedented. In addition to Samsung, NXP Semiconductors, Infineon Semiconductors, and others were forced to take similar measures.

It is still impossible to restore the work of the factories.

-

TSMC has prioritized expanding 12-inch fabs over 8-inch ones, and it may be easier for the foundry house to squeeze in extra orders from some clients its 12-inch fabs in the second quarter, according to industry sources.

12-inch based production has lot of issues, including much more defects in source material.

TSMC hope that lot of small chiplets and such 4-5nm things will allow it to still be more profitable.

-

Qualcomm will continue to fabricate its next-generation 5G mobile chip, tentatively dubbed Snapdragon 895, at Samsung Electronics built using an upgraded 5nm process, but may switch to TSMC in 2022 using its 4nm process, according to industry sources.

Samsung has severe issues now with making GPUs, makes lot of silicone waste still.

TSMC also nearly full progress stop and try to keep everything almost same in 4nm version, as they can't jump to 3nm still.

-

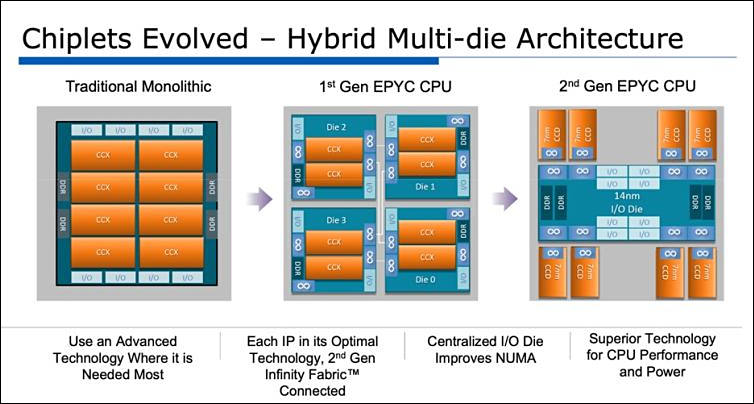

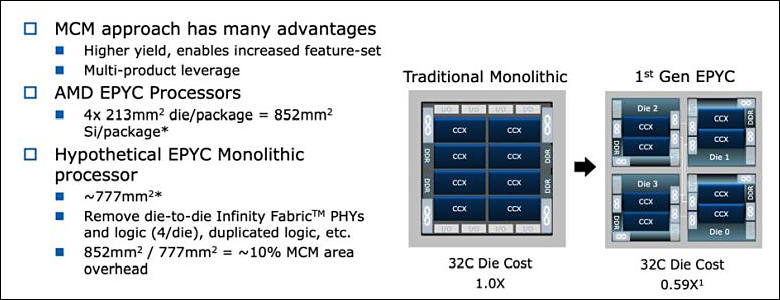

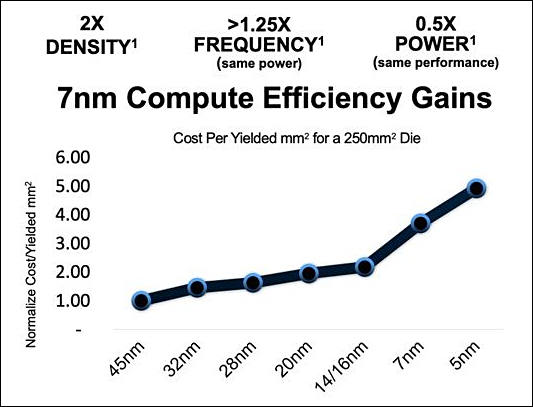

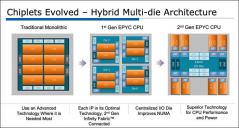

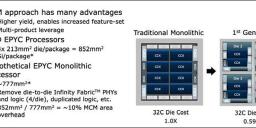

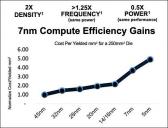

AMD Chiplets

sa16584.jpg754 x 404 - 63K

sa16584.jpg754 x 404 - 63K

sa16585.jpg780 x 300 - 50K

sa16585.jpg780 x 300 - 50K

sa16586.jpg533 x 407 - 33K

sa16586.jpg533 x 407 - 33K -

According to J.P. Morgan, semiconductor supply volumes in various industries are 10-30% lower than the needs of these industries. In order for the industry to be able to increase production volumes, it takes from 6 months to a year. Accordingly, throughout this period, we will observe problems with the supply of various systems and devices where chips are used.

According to various analysts, the reason for the deficit is that under the influence of the pandemic everything and everyone is being digitalized, company employees work remotely, and the demand for equipment and, accordingly, chips is increasing. But the industry, with all its desire, is not yet able to increase production volumes.

In reality we have two things:

- Capitalist owners just get record profits and do not want to increase production as long as they can

- 5nm and up require huge direct newly printed money injections that are no impossible to hide (TSMC will get around 100 billions from US and EU, free of charge). This was TSMC and few other giants are no longer even remotely independent companies, but more like governments war machines.

-

TSMC has issues with scaling 5nm

TSMC is slow expanding capacity for 5nm process to meet strong demand from a host of heavyweight clients, including Apple, AMD and MediaTek. The foundry house's capacity for 5nm process is expected hike only by one third in second-half 2021 compared to that in the last quarter of 2020.

5nm capacity now is mostly being distributed during talks with US government as they determinate who will get the ability to make such chips and who will get free money to get equipment.

-

Recently Taiwan authorities asked manufacturers to reduce the consumption of water for production. This is the second order in two months. In January, large producers were advised to reduce their water consumption by 7%, and a new order requires an additional 11% reduction in the cities of Taoyuan, Taichung, Hsinchu and Miaoli. This directly affects TSMC and other semiconductor manufacturers, but the authorities assure that everything is under control.

TSMC, UMC and other manufacturers have implemented a number of dynamic water allocation measures for the Hsinchu Technology Park. Against this background, there were even rumors that the authorities in 60 days will stop the supply of water to technological parks, but there is no official confirmation of this. However, it should be expected that if the drought gets worse, the ministry will be forced to take more drastic measures to regulate water consumption.

Taiwan is worst place for chips production, best place is in the middle of big tectonic plate (biggest costs go to ensure stability) and with lot of water, cheap electricity and other stuff. Yes, I mean Siberia, but this is not an option for capital now.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- Topics List23,990

- Blog5,725

- General and News1,353

- Hacks and Patches1,153

- ↳ Top Settings33

- ↳ Beginners256

- ↳ Archives402

- ↳ Hacks News and Development56

- Cameras2,367

- ↳ Panasonic995

- ↳ Canon118

- ↳ Sony156

- ↳ Nikon96

- ↳ Pentax and Samsung70

- ↳ Olympus and Fujifilm101

- ↳ Compacts and Camcorders300

- ↳ Smartphones for video97

- ↳ Pro Video Cameras191

- ↳ BlackMagic and other raw cameras116

- Skill1,960

- ↳ Business and distribution66

- ↳ Preparation, scripts and legal38

- ↳ Art149

- ↳ Import, Convert, Exporting291

- ↳ Editors191

- ↳ Effects and stunts115

- ↳ Color grading197

- ↳ Sound and Music280

- ↳ Lighting96

- ↳ Software and storage tips266

- Gear5,420

- ↳ Filters, Adapters, Matte boxes344

- ↳ Lenses1,582

- ↳ Follow focus and gears93

- ↳ Sound499

- ↳ Lighting gear314

- ↳ Camera movement230

- ↳ Gimbals and copters302

- ↳ Rigs and related stuff273

- ↳ Power solutions83

- ↳ Monitors and viewfinders340

- ↳ Tripods and fluid heads139

- ↳ Storage286

- ↳ Computers and studio gear560

- ↳ VR and 3D248

- Showcase1,859

- Marketplace2,834

- Offtopic1,319