-

Hey guys, just wanted to show you what i am working on for a while. This is our final rig, i made from lot of companies stuff all around the world :) I am really proud of it :) It is very customizable. http://www.studio-x.hu/Image/rent/cinemaRIG2.jpg

-

@Psyco Awesome colour --- I think you'll find many people prefer a big knob!

-

I'm not a fan of touchscreens as you always have to look at it when using it. A (big) knob and some buttons you can feel is something I prefere, so you can concentrate on the video picture not the tool.

But for strikt preset curves a smartphone or laptop would be ok.

-

I chose proper colour for the remote ;-)

Looks cool.

What do you think about idea to use cheap Android smartphone with capacitive screen and special application as remote? So your preset position will be visible as lines, and you can use your finger movement instead of wheel.

-

@CHARPU I'm so busy working on the remote FF that I had no time writing an update but I can give a small overview.

The first version was already tested at a small film project at school. It was still all in a very early prototype stage but worked just fine:

Remote with 7-digits-display and receiver (open to prevent it from overheating)

I'm now using a bigger stepper motor that just fits at the side of the big lenses with no additional gear. The ring motor is still not finished as I'm having serious problems with the glue (!) as it can't hold the tiny but freaking strong magnets in place - maybe I can finish it during the next holidays.

At the moment I'm working on the new version of the remote and receiver - smaller, more durable, better displays,...

@Vitaly_Kiselev I chose proper colour for the remote ;-)

Sender.jpg640 x 686 - 81K

Sender.jpg640 x 686 - 81K

Empfanger.jpg640 x 670 - 107K

Empfanger.jpg640 x 670 - 107K

EmpfangerNeu.jpg640 x 727 - 107K

EmpfangerNeu.jpg640 x 727 - 107K

SenderNeu.jpg640 x 587 - 83K

SenderNeu.jpg640 x 587 - 83K -

hey @psyco ! any progress on the follow focus? I am still waiting for somebody to come up with something wireless and fordable... thanks!

-

@goanna Thanks! After doing some research, it seems I will have to make the motor myselfe.

(After trying to get several parts for my rig from specialized companies, I can say: German companies have to much money and are not interested in business, they are fucking stupid!)

The basic design is already finished, I'm now trying to get the parts.

@Meierhans I'm not sure about sharing to many details - if its for the regular members of this forum (like you), I would have posted all plans already. But I don't want to see my hard work beeing used by companies selling it for a lot of money without even giving me credit for it. Designing the aluminium parts or writing the code for the Arduino took a long time, was a lot of work and needed quiet some skill. I want to keep the option of selling this knowledge or even starting to produce some type of wireless FF myselfe.

But don't worry, you can just make your own programm doing pretty much the same as mine by copy/paste-ing the code from the examples that come with the Arduino and using there libraries - it will be much bigger and a bit slower, but I think it will still work. (Use a potentiometer instead of the puls encoder - not as precise, but you get sample code for free.)

I can't use any additional gears with the stepper motor, as its already quiet slow - doing only 1.8° steps and having a limited maximum step frequency it would just be fast enough for good focus work as it is now. Using gears and slowing it further down would make fast or rack focusing impossible. And as it seems, there are no 7.5° stepper motors in that size avaluable.

-

I am still very interested into DIY wireless FF. Do you plan share project details and code for arduino? Did you try planetary gears on the stepper?

-

Buying or building a ring motor.

A brilliant idea and a simplified, elegant design. I don't know if IntelliDrives manufacture anything that will suit exactly, but they'll point you in the right direction.

I expect you to go on to think up simpler ways to control it, too - based on your current prototype. Great work!!

-

@rockroadpix Looks like a very compact rig - perfect for run n' gun situations.

-

So, I wanted to give short update about the wireless focusing system (especially after seeing this http://www.personal-view.com/talks/discussion/5015/wondland-wireless-follow-focus-system-on-ebay ).

I tryed the USB backchannel of the wireless HDMI system and was even thinking of using the remote control backchannel, but non of these worked the way I need it, so I gave up that idea and had a look at the wireless options for the Arduino.

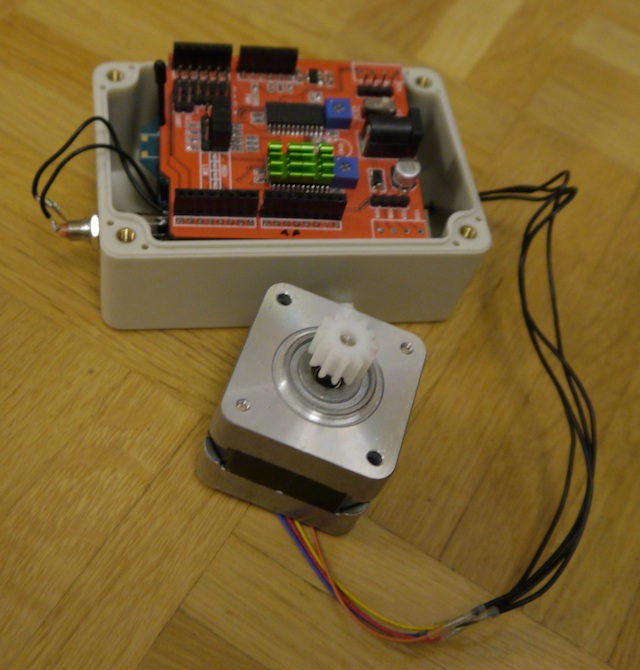

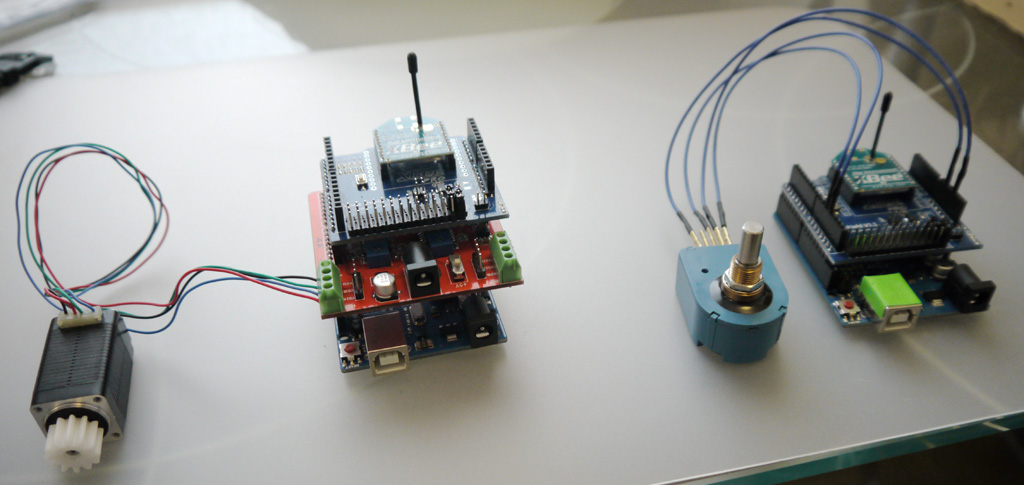

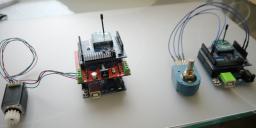

Its really freaking easy. I'm using a Xbee transmitter/receiver on both Arduinos and setting it up is a walk in the park. The system consists now of:

2 Arduino boards (blue boards at the bottom with USB connectors)

2 Xbee breakout shields and Xbee modules (blue boards on top with small antenna)

stepper motor shield (red board)

stepper motor

puls encoder (bare encoder, knob not installed)

All in all, about $200 and I was not looking for the best price (good documentation was more important for this first parts).

The puls encoder has a resolution of 500 pulses per revolution. The position of the knob is processed by the Arduino and then send via the Xbee modules to the other Arduino. There the position is used as the mark where the stepper motor will stop. Its easy to modify the relation between input and output speed, so setting the motor to turn faster or slower than the input knob is no problem. Even recording focus pulls and then playing them back would be no problem. And it always works perfectly repeatable and to a precision of < 1° .

The only problem I have at the moment is the small stepper motor. As mentioned above, Olympus refuses to un-dampen there lenses and the Nema8 motor is just at its limit by pulling the fokus ring of my 14-35mm F2.0 - it is no problem using the motor with my Tokina 11-16mm F2.8 so. The controller board can handle much bigger motors, but I can't fit a bigger motor under the huge Olympus lens.

I'm working at a solution to this last problem: Buying or building a ring motor. A stepper motor that goes direktly around the lens. There would be no need for cog wheels, there would be no play and it can be very silent.

Wireless-Setup.jpg1024 x 485 - 151K

Wireless-Setup.jpg1024 x 485 - 151K -

My "rig" - Not a "cinema", but "typical run around an event" rig...

I still had my Zacuto eyepiece and I wanted to use it with my cage, so I got an articulating arm with a 15mm rod clamp w/ 1/4-20 and voila! I sealed it with black paper tape. and I think it looks pretty cool.

IMG_0857.jpg2592 x 1936 - 3M

IMG_0857.jpg2592 x 1936 - 3M

IMG_0858.JPG2592 x 1936 - 2M

IMG_0858.JPG2592 x 1936 - 2M -

-

@psyco I dont hv a problem and I am secure in who I am. Btw I dun stinge on my gear either. If you want to play in the big league learn to save up and buy real equipment. I use red rock and manfrottos, not DIY stuff that kids use in schools :)

-

I have been admiring your assiduous work and your readiness to share each episode with us. What makes the ongoing story more compelling is that you've sought our advice at times.

At first I wondered whether you'd gone through thorough testing at the design stage; now, as you reveal your fast-tracked, metal apprenticeship, I realise what a dark horse you are.

As a self-paced novel, this is character development wound around a techie theme. As media, it's a compelling, new genre. I hope the project's a success and a book sales income will help recover your investment.

-

I mean new, as new to this forum. And no, the GH2 is not my first camera.

And whats your point? Having no rig doesn't make me a better cameraman either. I built that rig because I can. It was fun (most of the time). And buying something that comes even close to this would have cost much more than I'm willing to spend. I spent about 1/100 of the cost of a Steadycam or Sachtler or Arri.

I wanted one piece of equipment to make shoots with camera movement - my decision was: camera stabiliser, because its the moste versatile option.

So, whats the problem? If you also want one - sorry - there is only this prototype;-)

-

Seriously Kazuo, let the man(*) use the cam he want the way he want... giving the effort he's putting into building his rig, I think he clearly know why this cam and not another (certainly not to look "impressive"). Some people like to build very complicated stuff (a steadycam with a motorized FF, damn!) I barely know how to change a bulb but it look fun...

(*) either a noob or a legendary god-giffted DP collecting Angenieux lenses since his coffin - who care ?

-

I am not new. I have been doing film and media for 15 years. I don't profess to know alot, but I am not new ;) I started collecting Carl Zeiss and Leica lenses 10 years ago, and I have a substantial suite today, so i know abit about vintage glass.

IS GH2 the first and only camera you've used in your life?

All I was trying to point out to you and everyone who's reading is that sometimes it's not necessary to spend so much money pimping your camera in a certain way. An impressive looking rig will not make you a better cameraman. Even if you disagree, you dun have to be dismissive my friend.

-

@ipcmlr The 35-100mm is focus by wire, but the 14-35mm is friction coupled and would be accurate if you don't turn it beyond the end points. As I'm using it with an external monitor and a dedicated focus puller, it would even work with a focus by wire lens (but it would still be a pain in the ass;-).

@kazuo If you are new you should read up a bit more about some things first. This forum is all about hacking the GH1 and GH2 and there are patches with very high bitrates and all I-frames around.

I'm using a GH2 because its cheap, light, versatile, has a good sensor and lenses are interchangeable (good glas is very important).

So, please don't turn this thread into a "why this or that camera"-thread, there are better places in this forum for things like that. This one here is about (DIY) camera rigs people put together and find usefull.

-

What are you getting out of yr small camera, regardless of the size of its sensor? 24, 28 mbps at best? The Varicam will give you AVC Intra 100 without batting an eyelid. If you are using any DSLR, you need to hack your camera to get there. Or better still, try an external recorder, and hope it yields very clean results without more work in post.

I came over to DSLR because I could no longer handle huge cameras because of back and shoulder pains. What are your reasons?

-

@psycho quick question. Isnt the olympus lens focus by wire? Was looking to get them but was afraid a follow focus would not be accurate a lot of times. Does it work well with a FF? Thanks.

-

And what do I want a small sensor kamera for? The rig is a steadycam system - no kamera has that built into it. Without that its a pretty small and lightweight camera/rig.

If you doing handheld homevideos, than I do agree that a Varicam or this rig is overkill - but thats not what I intend to do;-)

-

Haha i ditched my Varicam to go DSLR, and here you have people spending good money turning their small cams into monster machines. With that money spent on the carcass, you could have bought yourself a used broadcast camera.

-

@dumile sorry, didn't see your post until now (don't add a space between @ and the name or I won't see it as a reply;-).

First: Be carefull, this professional machines are dangerous - you might loose an arm or be dead before you know what hit you. I would advise you to get your brother show you how everything is done properly and that he is allways near by, just in case.

Sorry, but I can't help you with books or forums. I had a basic training for about 3 month, starting with cuting steel by hand, drilling 10000000 holes, cuting threads, measuring,... all by hand or with small machines. Just after leraning all this (and getting some bleeding fingers) I learned about how to use the big machines. I had a dedicated teacher that would "explain" things to me. It wasn't hard for me to learn all this in such a short time (normally its done in about 2 years), as I have worked with wood for years (and I might have some talent for things like that;-).

I have also designed lots of other things/parts before. Its nothing you can learn from a book. You just have to try, make mistakes, try again and develop your own workflow. Technical drawings help a lot (thats something you can learn from a book, but that needs practice too). And its always a good idea to look how it has been done before - I got a lot of ideas from the Steadycam and Sachtler pictures on the internet.

After getting a first design of the whole system I start looking at the individual parts. I try to think it that way: 1) Whats the purpose of the part/what do i want it to do? 2) How will it look/how strong has it to be? 3) Does it fit into the rest of the project/Can I reach all screws when its in place? 4) Do I like its look/does it feel right? ....after doing that for every part, I start all over again till I'm sure I won't waste 100 hours on some parts that don't work;-) For the most complex parts and especially to test if they will fit with all other parts I used a 3D programm. I used Cinema 4D and in one case even made a stereoscopic video of some parts rotating to check if they really fit.

After all parts were designed and all technical drawings were finished, I startet cutting them. I just got some aluminium blocks from Ebay, a small milling machine (its normally only used to cut wood) and drilling machine from a store, and the cross table again from Ebay. It does make a horrible sound when cutting through a solid block of metall and is not really save (but I still have all fingers and eyes;-). First make a raw cut to just get some material out of the way. Second do a fine cut to get everything like planned. For aluminium you should work as precise as 0,05mm when parts have to fit into each other. If its no special part you still should be as precise as 0,2mm. Try to work as precise as possbile at the start, things will get worse by itselfe:-P

I didn't treat the raw aluminium parts in any way. It will get dull by itselfe after a some time. So, I will paint the whole rig black when everything is finished. But I still have to design and built the arm and vest and I don't have the time for it at the moment. And thanks to (fucking) Olympus I have to redesign the wireless focus unit first:-(

I hope there was at least a littel bit of usefull information in this very long text. Oh, and one thing - it was a very nice feeling after cutting/drilling/... for about 2 years when I could assemble the whole rig for the first time...very nice :-)))

-

FUCK OLYMPUS SUPPORT!!!! Sorry, but I'm really pissed.

All is working fine, I can controll a little Nema8 stepper motor with the Arduino, the motor fits just under the lens, turns the focus ring on my Tokina 11-16 smooth and precise, but...

...but not on my (fucking expensive) Olympus 14-35 and 35-100 lenses because the focus ring is just way to hard to turn. To much for the little motor.

So, I contacted Olympus Support by email and asked, how much it would cost to reduce dampening on the focus ring. Answer, sorry but you have to send the lens in for any repair, we can't tell you anything without seeing the lens.

Next try, via email. Trying to explain that I don't need to send my lens to them, because it is no different to a new one next to the tech guy. Answer, sorry, blablabla...you have to send it in.

Third try, phone. Explaining the "problem" again (after 30min the call centre guy finally understood what I want). Answer, he will ask a tech guy and phone back.

Fourth try, phone. After not getting any recall I just called them again. Answer, it is not possible.......(WTF?)....he asked two(!) tech guys, and it is absolutely not possible for Olympus to change the dampening on there own Top Pro lenses.

Bottom line, I know that the dampening can be changed on every lens as its nothing else then controlled friction (normally a grease is used), but Olympus refuses to do such a thing even with there Top Pro lenses (and we were not even talking about a price point for the job). Thats exactly the kind of "support" that will drive pro user to use products from another company. No I'm sitting here with two very nice lenses and just thinking of getting rid of them :-(

-

psyco that rig is fantastic. I plan on building my own in the near future and any advice you can provide me with would be greatly appreciated. My brother is a mechanical engineering student so I have access to any machine I would need (CNC, lathe, drills etc.) But he's very busy with studies so he wouldn't be able to help much with the actual design/build.

You said you cut everything from solid aluminum blocks - how did you go about doing this? Some of those parts looks very complicated. Also, can you show me any resources (books, forums) you used for direction? Lastly, did you anodize the parts? I did some research yesterday and it seems to be a fairly simple project.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- Topics List23,992

- Blog5,725

- General and News1,354

- Hacks and Patches1,153

- ↳ Top Settings33

- ↳ Beginners256

- ↳ Archives402

- ↳ Hacks News and Development56

- Cameras2,367

- ↳ Panasonic995

- ↳ Canon118

- ↳ Sony156

- ↳ Nikon96

- ↳ Pentax and Samsung70

- ↳ Olympus and Fujifilm101

- ↳ Compacts and Camcorders300

- ↳ Smartphones for video97

- ↳ Pro Video Cameras191

- ↳ BlackMagic and other raw cameras116

- Skill1,960

- ↳ Business and distribution66

- ↳ Preparation, scripts and legal38

- ↳ Art149

- ↳ Import, Convert, Exporting291

- ↳ Editors191

- ↳ Effects and stunts115

- ↳ Color grading197

- ↳ Sound and Music280

- ↳ Lighting96

- ↳ Software and storage tips266

- Gear5,420

- ↳ Filters, Adapters, Matte boxes344

- ↳ Lenses1,582

- ↳ Follow focus and gears93

- ↳ Sound499

- ↳ Lighting gear314

- ↳ Camera movement230

- ↳ Gimbals and copters302

- ↳ Rigs and related stuff273

- ↳ Power solutions83

- ↳ Monitors and viewfinders340

- ↳ Tripods and fluid heads139

- ↳ Storage286

- ↳ Computers and studio gear560

- ↳ VR and 3D248

- Showcase1,859

- Marketplace2,834

- Offtopic1,320