Manual lens rebuilding

-

Here is good video about Pentax lens disassembly

-

All of the above (FD 300/2.8L) and these 3 below (FD 300/4L) are pretty close to 100% crops too if not actually.

(These are HTML scaled so to see the ~100% crops unscaled (in Safari for example) just right click and select "Open In New Window" or Tab.)

Of these Oly 300/4.5T shots most are also heavily cropped:

I hope no one minds the image flood. That's my fun for the week anyway. O :-)

-

Re: http://tech.groups.yahoo.com/group/NikonRepair/message/262

Nikon put a stop to selling repair supplies some time around the release of the D80. They won't sell grease or software to anyone except authorized repair depots, and there are not many of those left. One lubricant (G-92KA Floil) is not even available from the Japanese manufacturer, as it was produced in collaboration with Nikon. -

Hi folks:

I'm the eBay seller with the grease! Thanks for the links.

I brought these in from Japan as it is pretty much impossible to find decent lens greases in small quantities. One company you mention above has them but they are charging an arm and a leg for them...

So I figured why not get a few kilos and sell them in small quantities. No complaints so far. Also, it was a bit of a challenge to find this stuff, and I like a challenge.

Re the composition of the greases, and for the sake of expanding the knowledge on the black art of lens greases, the only data I have for them is below, extracted form the MSDS. The main thing I get from this is that there seem to be no organic components (i.e. oil), unless "Synthetic hydrocarbon base oil" is a way of saying "we made oil in a lab, because it is better." Wikipedia says you can make synthetic oil from non-hydrocarbon chemicals, or from real oils... and that "Synthetic oil is used as a substitute for lubricant refined from petroleum when operating in extremes of temperature, because it generally provides superior mechanical and chemical properties than those found in traditional mineral oils."

In any case, here's the only data on the composition that I could get:

• FC-4 (thickest, used for Helicoids and cams and the like)

40-50% Synthetic silicone base oil

40-50% Synthetic hydrocarbon base oil

< 5% Lithium soap thickener

5-15% Additives(Fluoropolymers, etc.)

• GE-8 (lighter than FC-4, for cams and slots)

75-85% Synthetic hydrocarbon base oil

5-15% Lithium soap thickener

5-15% Additives(Fluoropolymers, etc.)

• I-40 (used for metal gears mostly, as in the AF "drive train")

55-65% Synthetic hydrocarbon base oil

10-20% Synthetic silicone base oil

5-15% Lithium soap thickener Additives

10-20% Additives (Fluoropolymers, Molybdenum disulfide, etc.)

Daniel -

Yeah, for customizing the handling I can see trying different stuff. Of all the lenses I've opened I've only needed to re-grease a few. Mostly in my case I'm inside for the purpose of cleaning the lens elements, unsticking or de-oiling the aperture leaves, and etc. like that. And the few I re-greased were inexpensive (<$25) lenses I intend to keep for personal use. If I were going to do a customer's lens or an expensive unit I'd either get the material(s) directly from the manufacturer or I'd send it in and have them do it.<br />

I sure have come to notice that different manufacturers have very different notions about manual focus and zoom ring stiffness (dampening). Nikon and Olympus tend to be quite stiff while Pentax and Canon are typically adjustable with the light touch of just a pinky finger for example.

I'm spending most of my time shooting stills with MF lenses and I sure notice it a lot there too! I think the first time it really hit me was birding with the FD 300/4L. I liked it so much I went 300mm lens crazy and tried a whole slew of 300mm lenses (12 or 14 maybe). The one's like the 300/4L and the 300/2.8L were super easy to track those fun fast moving tiny foul while the stiffer ones like the Oly 300/4.5T and Nikkor (non-IF) ED 2.8 & 4.5 just weren't suited for it - tho were more "comfortable" to use with non-moving objects, like the moon or landscapes etc. I found this to be true with anything moving at all:

These are HTML scaled so to see the ~100% crops unscaled (in Safari for example) just right click and select "Open In New Window" or Tab.

and it really makes the difference in getting things tack sharp at wide(ish) apertures - or not. Since almost all video is moving (either the camera or the subject) it follows there too. I get much better results if a) I spend a little time getting to know the lens's throw for the distances I'll be working with and b) it's not dampened almost at all. And of course I'm sure you already know I'm not talking about lenses that are easy but also have rattle or play in the focusing mechanism - or like so many AF lenses have when set to MF. :(

Now if only the GH1 / GH2 had a decent continuous drive speed and buffer.... :P

-

thanks for the link to the Nikon grease.

I've read all about the nyogel and microtools grease. From what I gather the microtools grease is similar to the Dow brand Molykote greases. It's just a PAO grease with extra PTFE. However, microtools wants a fortune for the stuff. I found Molykote on EBAY for 3$ and tried it. It works but it does not offer much metal/metal protection. I could still feel the metal grinding with both small and large amounts of Molykote.

Personally I tried to find the lightest lubricant that would not allow the helicals to grind while still being very easy to turn.

Dampening greases tend to be hard to turn. It's fine for still photos but when you start using still glass on video cameras you start to notice how hard it is to turn when you start using things like follow focuses. -

svart, have you seen this yet per chance?

http://tech.groups.yahoo.com/group/NikonRepair/message/262

"For the real thing buy your lens greases directly from Nikon ½ ounce of Af lens greases is $6.00 Part # *FC-4 (good for 10 to 15 lenses). ½ ounce of Photo Lube (great for M. focusing lenses) is $6.00 Part #*EBB3011 (good for 10 to 15 lenses). Shipping and Handling is $10 per order. Phone number is 310 516-7124"

:) -

I just read your 3rd post svart. That's good info - thanks!

VK, yeah, some retaining rings are inset and of a larger diameter that the opening we're working through so that angle is sometimes needed. Thankfully not too many are like that but some are. -

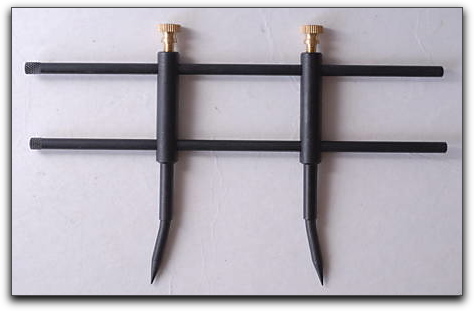

@Tesselator

I also fully agree with your addition that tips of wrench must be angled.

I looked at my wrenches and realised that they are not the same as ones in the my first post.

They are similar, but better quality and tips on bth wrenches are angled. -

I just followed svart's link... that looks like the "gorilla snot" I was talking about. It's a heavily dampening grease so be sure that's how you like your lenses to behave - or how they behaved originally if restoring to original.

EDIT:

I just noticed his description reads:

"I-40 is typically specified as the grease to use on the AF drive gear components." So probably not what to use on the helicoid threads. ;)

EDIT EDIT:

Oh, jeez, there's two different kinds. FC-4 is the helicoid grease. OK, got it. :D

hehe... -

-

Most probably second wrench uses some kind of coating.

Plus most people will be using it on one-two lenses, so steel used is not very important.

I have wrenches from first post myself and they are working fine. -

good post!

Yes, oils are generally frowned upon because they wick along metal surfaces. Oils come in a variety of surface adhesion properties though, just like greases. Greases and oils are not that far removed from each other in reality as grease is generally oil with a silicate thickener. "Lithium grease" is lithium soaps suspended in an organic oil medium and the "drying out" is just the hydrocarbons being slowly released from the medium leaving the solids behind. Unfortunately this is all generic though as there are probably thousands of different kinds of "lithium greases" with only a few with the stable properties needed for lenses.

From my research on modern helical greases, most, if not all are now PAO synthetics filled with PTFE(teflon, also a flouropolymer). The base stocks in synthetic oils such as automobile engine oils are also PAO but without the silicate thickeners to make them into greases, however they do have hydrocarbon additives that make them unsuitable for lens use as they WILL outgas things that will mess up optics by coating them, thus my search for a moderately adhesive PAO based PTFE filled oil that is stable through temperature. I even took a junk lens and heated it with a torch to see if the PAO based would separate and run and it did not even when smoking.

I used moly grease in a lens for a month and then opened it back up. The moly grease had traveled considerably throughout the lens and it was much darker than when I put it in showing increased wear of the aluminum helicals. It's meant for high pressure, high hardness metals such as bearing races and stuff, not soft aluminum and the base oils were organic and not stable as they separated and ran when exposed to heat.

To each his own though, and I can't say what I did would work for anybody else. I'd advise doing as much testing as possible, preferably on a broken lens first. -

A couple of things from me... I've rebuilt 62 lenses in the past 16 months according to my spreadsheet. :)

1) Oils are generally not a good idea because in a heated condition like on a summer's day, the oil can actually evaporate and then condense on the glass (lens) surface. Also some oils will spread out to one molecule thickness by nature. If this gets on a coated lens or a doublet/triplet/quadruplet there is a chance it can get in-between and cause coating or lens separation. Silicone based oils are known for this - others may also be. Best case - unless you really know your oils don't use oil.

2) Of all the lenses I've opened (62) all but a tiny minority used just plain old white lithium grease. It's not thick (although there are different weights) but as many of you will know, it can dry up after about 10 or 20 years - depending on the environment and storage conditions. Well kept, it can last very much longer - maybe 50 years or so. If you're regreasing a lens I've found it best to use a Q-tip lightly saturated and apply sparingly re-dipping the q-tip for about every cm^2 you cover.

Of the ones that were not white lithium grease I can possibly identify some as molybdenum disulfide grease. Molybdenum is a metal-like substance (something like graphite) which they suspend in emulsified thixotropic or "shear thinning" fluid: AKA grease. :)

Some lenses use only fluoropolymer parts with no other lubricants at all. Fluoropolymer it that (usually) white translucent plastic used for parts or linings when parts need to slide smoothly. Like in your DVD drive or on the bottom of your mouse. There's many kinds of fluoropolymers.

A couple of (old) lenses have had monkey snot in them but it's unclear to me if that was added later by some repairmen or was used originally by the factory. I dunno the make-up of monkey snot or gorilla snot but in a office equipment factory I worked in (as a security guard) where copy machines were made, there were large drums labeled "GORILLA SNOT" and "MONKEY SNOT" which were two different weights of dampening grease - black-ish green, odorless, and looking just like their namesakes. I think I recognized that stuff (whatever it is) in two lenses that I took apart. They were very stiff - but very smooth too if you get me. I didn't replace it in those cases. That was probably it's original design and the snot was still snotty so I just left it - I mean besides cleaning all of the other surfaces for the rebuild.

3) If you need spanner wrenches try to find black ones. Black is usually an indication that high-carbon steel is being used. High carbon (tempered) steel is preferred as the tips will stay sharp - thus won't jump out of the slots, thus will reduce the likelihood of scratching the glass or marring the ring faces - etc. If you already have silver ones you can temper them yourself. Get a propane torch (can) and heat up the tip areas to /juuuust/ red glowing. Then immediately submerge it in cold water. Wala - hard tempered! And now black too! ;) I have the ones similar to those shown in VK's first post BTW but with curved tips - which is critical for some lenses.

For the ID face rings try to avoid using these all together though. Instead use those rubber doughnut things. Orders of magnitude safer and there will be no signs of entry at all! I have this set and they work great:

SafariSnapz_001.jpg474 x 311 - 39K

SafariSnapz_001.jpg474 x 311 - 39K

tool9set.jpg704 x 955 - 321K

tool9set.jpg704 x 955 - 321K -

Other interesting spanner wrench.

http://cgi.ebay.com/Pro-Spanner-Wrench-Lens-Repair-Tool-Stainless-Steel-/260769561268?pt=LH_DefaultDomain_0

I still prefer separate wrenches as you do not have any dangerous things on top that can hurt you while you screw or unscrew things.

IMG_6555-1.jpg500 x 500 - 73K

IMG_6555-1.jpg500 x 500 - 73K -

Btw, I recommend to get this:

http://cgi.ebay.com/Pro-Spanner-Wrench-Set-2-repair-tool-lens-openning-/110529627228?pt=LH_DefaultDomain_0

Only about $45 shipped. -

I have a nikon 105mm that I might be rebuilding soon. I'll take pictures when I do.

I understand about the branded items and availability in other countries. The problem is that I haven't been able to find anything like this "superlube 51004" from any other company. I think it's pretty proprietary. In any case, you can get it from EBAY easily.

I also noticed that there is now an EBAY seller that is selling OEM Nikon lens grease. This is something new that was not available when I did the grease comparison.

http://shop.ebay.com/terminalcity/m.html?_nkw=grease&_sacat=0&_odkw=&_osacat=0

-

@svart

I can't even say how I am interested in all this.

I have lens spanners and fixed few lenses, plus destroyed (not completely :-) ) other few :-)

Helicals are complete nightmare.

>Super Lube 51004

Problem with this is that branded lubes are generally completely different in each country.

I think that few photo, or even video guides of most common operations will be extremely useful.

For, example I want to see fixing helicoids on Vivitar 28-90mm.

Many of them have oil.

As far as I know it is one of the worst lenses to fix :-)

Start New Topic

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- Topics List23,992

- Blog5,725

- General and News1,354

- Hacks and Patches1,153

- ↳ Top Settings33

- ↳ Beginners256

- ↳ Archives402

- ↳ Hacks News and Development56

- Cameras2,367

- ↳ Panasonic995

- ↳ Canon118

- ↳ Sony156

- ↳ Nikon96

- ↳ Pentax and Samsung70

- ↳ Olympus and Fujifilm101

- ↳ Compacts and Camcorders300

- ↳ Smartphones for video97

- ↳ Pro Video Cameras191

- ↳ BlackMagic and other raw cameras116

- Skill1,960

- ↳ Business and distribution66

- ↳ Preparation, scripts and legal38

- ↳ Art149

- ↳ Import, Convert, Exporting291

- ↳ Editors191

- ↳ Effects and stunts115

- ↳ Color grading197

- ↳ Sound and Music280

- ↳ Lighting96

- ↳ Software and storage tips266

- Gear5,420

- ↳ Filters, Adapters, Matte boxes344

- ↳ Lenses1,582

- ↳ Follow focus and gears93

- ↳ Sound499

- ↳ Lighting gear314

- ↳ Camera movement230

- ↳ Gimbals and copters302

- ↳ Rigs and related stuff273

- ↳ Power solutions83

- ↳ Monitors and viewfinders340

- ↳ Tripods and fluid heads139

- ↳ Storage286

- ↳ Computers and studio gear560

- ↳ VR and 3D248

- Showcase1,859

- Marketplace2,834

- Offtopic1,320

Tags in Topic

- lens 458

- lenses 152

- fix 9

- rebuilding 1