It allows to keep PV going, with more focus towards AI, but keeping be one of the few truly independent places.

-

Small thing to note - all Z mount lenses will have electronic focus rings made like on cheapest m43 lenses. No repeatable position, not usable with follow focus at all.

I had been told that management insisted on such construction as it cuts cost a lot, with new pricing and less glass used it allowed to set absolute margin records among all glass produced by Nikon.

Same goes new trend of USB charging, adds real nice value to top manager bonuses to improve their new yachts.

-

FWIW, I love USB charging. When I'm in places for a fairly extended period and I don't have access to a wall, big USB battery banks are a whole lot cheaper than dedicated spare batteries and can also be used to charge my phone/watch/flashlight/etc.

Sony gives a wall adapter as well as allowing USB charging - best of both worlds.

-

Very interesting Q&A in addition to previous posts

Q: What’s the Nikon Z7 production volume right now and what’s the yield?

A: Currently it’s 20k per month, the production yield target is of course 100%.Extremely unusual thing to tell production volume and with around 100% probability number was taken from the roof, just to make impression.

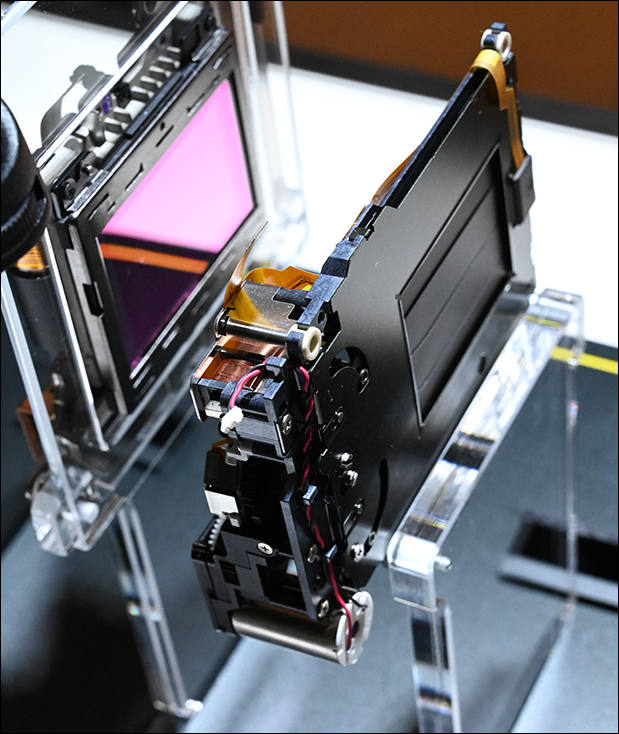

Q: We saw a lot of robots during the visit. What’s the percentage of automation for the Z camera production? Is it higher than the Nikon D series?

A: Currently our D5 automation percentage is about 55%, and the Z7 is 76%.Same here. How it happened that more automated (cheaper to make in volume) cameras have contantly rising prices (without any reason you can find)?

Q: Is this the only assembly line? We notice a lot of brass debris, are they going to be recycled?

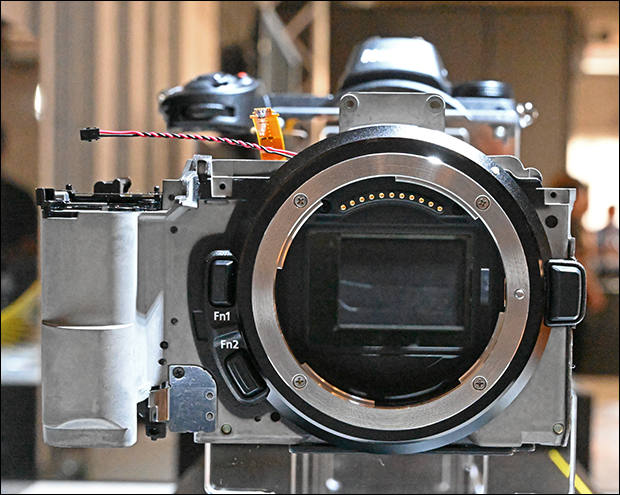

A: (long pause) What you saw today is the Z7 assembly line. Currently, the Nikon D5 and Df are on pause. We have another line for the film camera F6. A cleanroom is also in this shop. However, we didn’t visit the lens molding shop. By the way, metal debris from cutting will be processed by a specific recycling company.Q: What the decision criteria for using stainless steel vs. brass or other material for lens mount?

A: Currently stainless steel is used for lens mount in high-end bodies like D5 and D850, also the Z7. Brass is used in consumer models like the D5300. Brass is used in lens mount usually, and some entry-level lenses have a plastic mount. Note that the lens mount in the body may not all use stainless steel. We base on how frequent lenses are taken on and off to decide (the mount material).Fun observation - actual parts cost for this is around $2. So you can't find any scientific basis to save on this, except for management bonuses and investor profits.

Q: Is Z6 going to be made here?

A: We will build Z6 here but right now we are working full speed to make the Z7!It is actually exact same camera, just sensor differs, logo on body and firmware.

Q: What are the main responsibilities for the Nikon Thailand Plant?

A: The machines in Thailand factory are designed in Sendai and assembled before shipping to Thailand. All the automated machines in Thailand currently are designed and produced in Sendai. Of course, there is independent development in Thailand. Also, the automation levels in Thailand and Japan are different as we consider the percentage of automation based on costs.All capitalism logic in one sentence - if your work cost is lower you'll be doing pointless mechanical thing and we won't put robots that we could made. This is why all this must be wiped out.

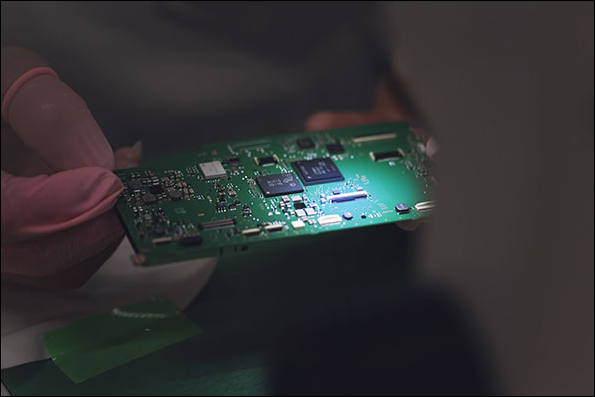

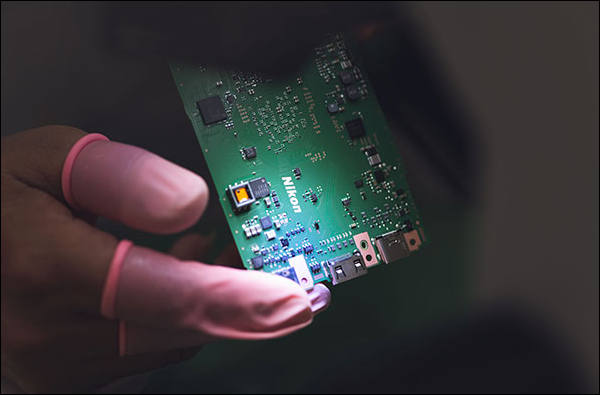

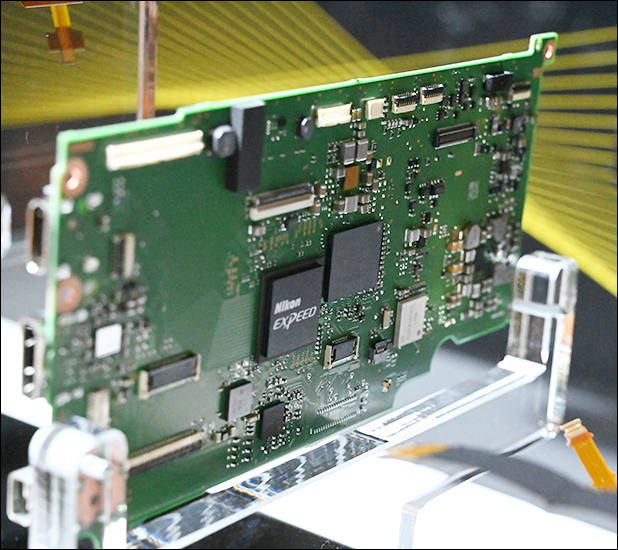

Q: Are all the parts made by Nikon? What percentage is the outsource parts, especially the CMOS (sensor)?

A: Parts made in Sendai include mounts, viewfinder lenses. Motherboards are also made in Sendai. About 80% of parts are purchased from outside companies. CMOS sensors are produced by our partner company based on Nikon’s requirements.So, Nikon does not make sensors, after all. PR miserable fail. And Imaging Resource editors full shame.

-

Supposedly the 15 minute video recording time was a typo on the website and has been updated to read 85 min record time on a battery charge. We won't know for sure until it's tested properly but it probably will not be as short as 15 minutes. That's entering BMPCC on original battery territory.

-

Nikon uses this lack of mechanical connection by offering a speed-sensitive response: moving the focus a lot if you turn the ring quickly or in more subtle increments if you move it slowly. It'll be unfamiliar if you're used to DSLR lenses but it can allow fast and precise focus once you're used to it. Nikon also let you use the focus ring for other functions, if you prefer.

However, this isn't the only way focus-by-wire lenses can work, and there's nothing to stop Nikon adding a linear response mode that would be more like the way its existing lenses operate.

None of other manufacturer added any linear response mode. I believe that with sensors they use this is not possible as they are not accurate and skip. Actual proper way is to use conductive sensor similar one used in digital calipers.

-

@Vitaliy_Kiselev Fuji added linear response option to there X-H1 camera. I never tried it so no clue how repeatable (dependable) it actually is.

-

Thanks for info, it is interesting.

Yes, testing of repeatability must be done. -

Anything to eliminate any traces of better old tech, even if we have to pay you.

Autofocus Is a big issue on z series

-

With condom on fingers ^^

-

@flash - That's called a finger cot - very useful when editing original film.

-

Lot of various info at IR

It seems like they became Nikon PR part.

https://www.imaging-resource.com/news/2018/08/28/nikon-z7-engineer-interview-deep-dive-q

sa4461.jpg618 x 550 - 72K

sa4461.jpg618 x 550 - 72K

sa4462.jpg620 x 495 - 63K

sa4462.jpg620 x 495 - 63K

sa4463.jpg619 x 734 - 76K

sa4463.jpg619 x 734 - 76K -

@4cardsman, it was a joke.

-

I did notice that Nikon seems to be showing cameras with firmware 0.5 (or 0.53). Typically a month before shipment I'm used to seeing 0.9x versions with Nikon. I don't know if that's meaningful here, but Nikon is a pretty anal and engineering nerd culture. They have a long-established step process they use. I just get the feeling we're seeing these cameras a little earlier in that process than usual (which also implies the process is getting time-compressed).

Thom H. (guy is very close to part of top Nikon management and is used as long pole to probe things in silent moment, during launches he plays full official PR role). Make sure to ignore complete bullshit he made up how second card slot is not important. As soon as Nikon will come with two slots he'll make exactly same thing how you must run to buy such camera.

My sources also tell that for Nikon it was only important to introduce cameras before Canon. No one cares for anything else. If you noticed Nikon and Canon PR departments played game with announcement leaks.

-

That's standard for any vendor. Every feature is completely unimportant to real people until they have it.

"Mirrorless cameras are cute toys, but real photographers use SLR's..."

(1 year later)

"Mirrorless cameras are the future! SLR's are dinosaurs!"

-

My sources also tell that for Nikon it was only important to introduce cameras before Canon. No one cares for anything else. If you noticed Nikon and Canon PR departments played game with announcement leaks.

Which they accomplished.

Guess it wasn't so important to Canon to be "first" & beat Nikon

-

More samples

https://www.dpreview.com/samples/1585173385/raw-conversions-added-to-nikon-z7-pre-production-gallery

sa4479.jpg800 x 521 - 120K

sa4479.jpg800 x 521 - 120K -

If Canon comes out with a full frame mirrorless with EF mount the party will be over for the Nikon Z mirrorless IMHO. Canon could trim the body down to the size of the Nikon Z7 using an EVF instead of an OVF/mirror box. The EF mount is about the same size diameter as the Nikon Z mount but has a zillion native lenses compared to only three native Z mount lenses !

Screen Shot 2018-08-30 at 6.17.20 PM.png1024 x 513 - 525K

Screen Shot 2018-08-30 at 6.17.20 PM.png1024 x 513 - 525K

Screen Shot 2018-08-31 at 10.14.31 AM.png894 x 793 - 517K

Screen Shot 2018-08-31 at 10.14.31 AM.png894 x 793 - 517K

Screen Shot 2018-08-30 at 6.43.08 PM.png744 x 541 - 406K

Screen Shot 2018-08-30 at 6.43.08 PM.png744 x 541 - 406K -

The EF mount flange distance is not a great fit for a mirrorless system, plus Canon will want to sell all new lenses since the market is already flooded with excellent EF lenses which have (more or less) reached their evolutionary apex. There's minimal/no reason to upgrade, for instance, from the 70-200/2.8II IS to the 70-200/2.8III IS. The latter is already an outstanding lens.

On the other hand, if they release a new mount where the existing lenses work pretty well with an adapter, but not quite as well as the fancy new native lenses, that'll encourage consumers to go out and spend thousands of dollars fleshing out the new system.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- Topics List23,911

- Blog5,718

- General and News1,330

- Hacks and Patches1,148

- ↳ Top Settings33

- ↳ Beginners254

- ↳ Archives402

- ↳ Hacks News and Development56

- Cameras2,342

- ↳ Panasonic984

- ↳ Canon118

- ↳ Sony154

- ↳ Nikon95

- ↳ Pentax and Samsung70

- ↳ Olympus and Fujifilm98

- ↳ Compacts and Camcorders295

- ↳ Smartphones for video96

- ↳ Pro Video Cameras191

- ↳ BlackMagic and other raw cameras116

- Skill1,959

- ↳ Business and distribution66

- ↳ Preparation, scripts and legal38

- ↳ Art149

- ↳ Import, Convert, Exporting291

- ↳ Editors190

- ↳ Effects and stunts115

- ↳ Color grading197

- ↳ Sound and Music280

- ↳ Lighting96

- ↳ Software and storage tips266

- Gear5,407

- ↳ Filters, Adapters, Matte boxes344

- ↳ Lenses1,577

- ↳ Follow focus and gears93

- ↳ Sound496

- ↳ Lighting gear313

- ↳ Camera movement230

- ↳ Gimbals and copters302

- ↳ Rigs and related stuff271

- ↳ Power solutions83

- ↳ Monitors and viewfinders339

- ↳ Tripods and fluid heads139

- ↳ Storage286

- ↳ Computers and studio gear559

- ↳ VR and 3D248

- Showcase1,859

- Marketplace2,834

- Offtopic1,314

Tags in Topic

- nikon 158

- mirrorless 15

- z 9